Quality Assurance Analysis is the strategic practice of examining how a product is built, tested, and released to ensure it consistently meets defined quality standards. In today’s fast-moving markets, delivering reliable products isn’t just a goal—it’s a necessity for customer satisfaction, brand credibility, and long-term profitability. Quality Assurance Analysis provides a structured approach to uncover risks early, align testing with customer expectations, and create a reliable roadmap for continuous improvement in QA. By focusing on analysis-driven decision making, teams can reduce rework, shorten time to market, and build a culture that values excellence in every release, monitored by product quality metrics. This aligns with QA analysis methods and the quality assurance process, translating quality goals into measurable terms and guiding stakeholders with clear metrics.

In other words, this discipline blends systematic inspection, verification, and governance to safeguard product integrity across platforms and teams. Seen through the lens of quality governance, teams pursue QA auditing, process standardization, and a robust defect analysis approach that targets root causes. By tying outcomes to product quality metrics and defect analysis linked to traceable requirements, organizations can forecast risk, prioritize tests, and demonstrate value to customers. Ultimately, the same aim is achieved through continuous improvement in QA, with an emphasis on automation, lightweight checks, and learning from each release. These alternative terms—verification, validation, and governance—support clearer communication while preserving focus on the quality assurance process, QA analysis methods, and defect-driven learning.

Quality Assurance Analysis: Integrating QA Analysis Methods with a Robust Quality Assurance Process

Quality Assurance Analysis serves as a structured framework that connects QA analysis methods to a comprehensive quality assurance process. By formalizing how data is collected, analyzed, and acted upon, teams can translate insights from design reviews, test results, and user feedback into measurable quality goals. This alignment helps ensure that quality expectations are embedded in every stage of development, from requirements to release, and that decisions are driven by evidence rather than intuition.

Practicing Quality Assurance Analysis enables organizations to define clear criteria for success and to monitor progress against those criteria using key indicators. When QA analysis methods are integrated with the quality assurance process, teams can articulate product quality metrics, track defect trends, and demonstrate that the product meets defined specifications across environments and user scenarios. This synergy supports a repeatable, audit-friendly approach to delivering reliable releases that satisfy customer expectations and strengthen brand credibility.

Defect Analysis and Continuous Improvement in QA: Driving Sustainable Product Quality

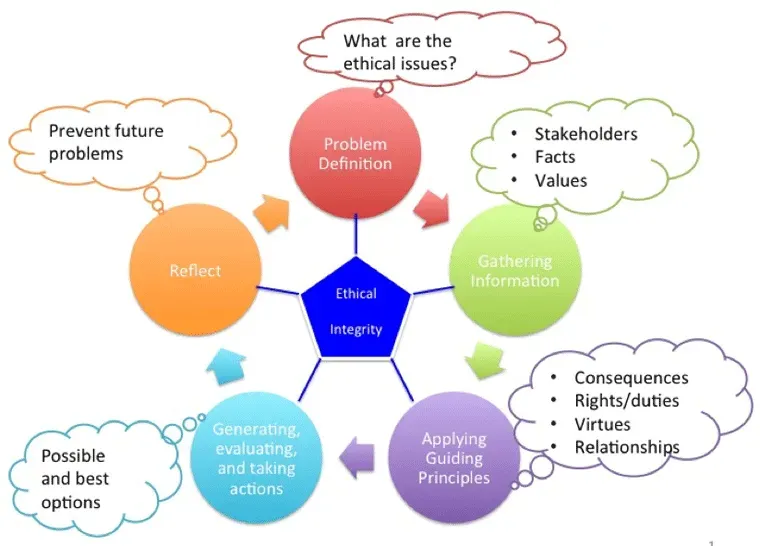

Defect analysis stands at the core of Quality Assurance Analysis, guiding teams to uncover root causes rather than just patch symptoms. By applying methods like root cause analysis, the 5 Whys, and Ishikawa diagrams, organizations identify whether failures originate in requirements, design, implementation, or testing. This disciplined approach feeds the continuous improvement in QA, turning lessons learned into preventive actions that reduce recurrence and improve overall product quality metrics.

To operationalize defect analysis, teams implement structured defect triage, robust data collection, and actionable dashboards. This enables visible traceability from defects to requirements and user stories, ensuring governance and accountability. With a focus on continuous improvement in QA, organizations can balance automation and manual testing, optimize test coverage, and allocate resources to high-impact areas, all while maintaining the velocity needed for competitive delivery.

Frequently Asked Questions

What is Quality Assurance Analysis and how do QA analysis methods improve product quality metrics within the quality assurance process?

Quality Assurance Analysis is the structured practice of examining how a product is built, tested, and released to ensure it meets defined standards. By applying QA analysis methods to collect and correlate design reviews, test results, defect logs, and user feedback, teams quantify alignment with requirements and track product quality metrics such as defect density, test coverage, and first-pass rates. This data-driven approach strengthens the quality assurance process, enables measurable targets, and supports continuous improvement in QA by guiding actions that reduce rework, shorten cycle times, and enhance customer satisfaction.

How does defect analysis integrate with the quality assurance process to enable continuous improvement in QA?

Defect analysis is a core part of Quality Assurance Analysis. Through root cause analysis techniques (such as 5 Whys or Ishikawa diagrams) and structured defect triage, teams identify why issues occur and implement corrective and preventive actions (CAPA). By linking defects to requirements and user stories, the quality assurance process gains traceability to prioritize risks and drive continuous improvement in QA via the PDCA cycle (Plan–Do–Check–Act). Over time, this yields better defect discovery, shorter repair times, and stronger product quality metrics.

| Key Point | Description |

|---|---|

| What is Quality Assurance Analysis? | The strategic practice of examining how a product is built, tested, and released to ensure it consistently meets defined quality standards. |

| Why it matters in today’s markets | Delivers reliable products to drive customer satisfaction, brand credibility, and long-term profitability. |

| Core purpose | Provides a structured, analysis‑driven approach to uncover risks early and create a roadmap for continuous improvement. |

| QA vs. QA Analysis | QA defines quality and processes; QA Analysis pulls data from design reviews, tests, defects, and feedback to quantify how well the product aligns with specifications. |

| Framework elements | Quality policy and standards; data collection and traceability; root cause analysis; governance and roles; continuous improvement. |

| Implementation plan | Define objectives with metrics and timelines; map the QA process, document steps, and establish data collection. |

| Metrics and dashboards | Defect density, defect discovery rate, test execution rate, requirement coverage, mean time to repair; balance leading and lagging indicators; use dashboards. |

| Defect analysis | Root cause analysis (e.g., 5 Whys, Fishbone) to address underlying causes and CAPA; informs risk prioritization. |

| Continuous improvement | PDCA cycle: Plan–Do–Check–Act; automate where valuable; balance automation with manual testing; drive learning across releases. |

| Practical practices | Clear requirements and testable acceptance criteria; centralized defect tracking; repeatable defect triage; lightweight automation; cross‑functional collaboration. |

| Case example | Mid-size product with annual releases: baseline defect density, quarterly RCA, lightweight automation; improvements in defect leakage, first‑pass outcomes, and customer‑reported issues. |

| What drives success | Tailor QA Analysis to risk, start with a sustainable data cadence, and scale governance and automation; phased approaches yield early wins. |